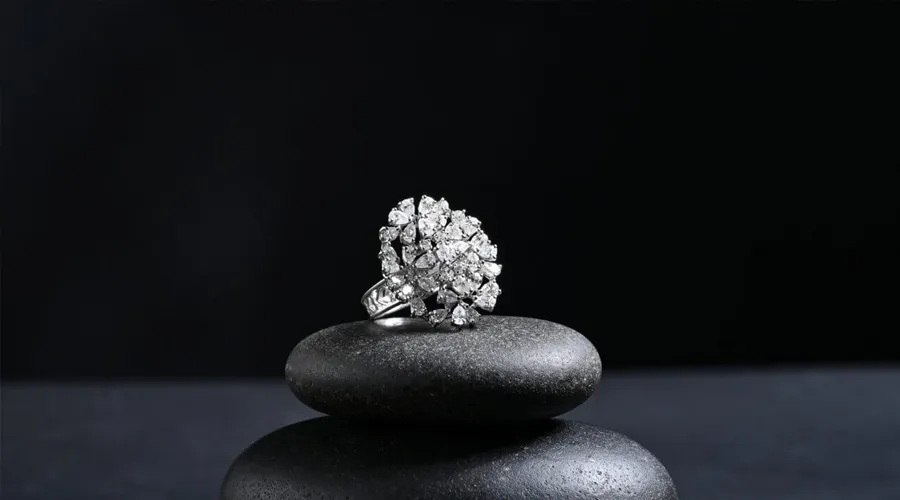

As diamonds advance relationships, diamonds also advance technologies. These gems help engineers with electrical isolation, thermal conductivity, optics, cutting tools, electronics and a lot more.

The share in sales value of synthetic diamonds went from 7.2% in 2020 to 22.0% in the start of 2023. In units (quantity of diamonds) we are almost at 50-50. For more information about diamonds click here.

The purest growing method is so called Microwave Plasma Chemical Vapor Deposition, you basically pull carbon-containing molecules apart and build the carbon together again as diamonds. A complex method that requires knowledge, advanced reactors, vacuum, plasma, gases and time, but the results are amazing!

Diamond is a high-strength and chemical corrosion-resistant material with broad optical transparency ranging from ultraviolet (UV) to infrared (IR) wavelengths. Diamond also has exceptional and advantageous features such as having a low friction coefficient, high thermal conductivity, high electrical isolation, low thermal expansion coefficient, and biological compatibility. These specifications make Diamond the perfect heat conductor, a desirable optic material, and a very reliable isolator for electricity.

The intake of gas flow is one of the very critical factors in diamond growth. Since the gases supplied to the system are directly added to the structure of the diamond, the measurement and control of the gas flow rate during the process are particularly decisive and important for a successful synthesis. Therefore, operating with accurate and precisely calibrated flow meters and controllers is critical. The rate of gases supplied must be consistent and stable, if not, the reaction could become unstable causing impurities in the diamond. Considering the process of building the diamonds can take weeks or even months, the mass flow controllers that are used to control the gas flow need to be accurate, reliable, and not influenced by changing temperatures and pressures. To control the pressure in the reactor they use the Vogtlin Electronic Back Pressure Controller that insures a stable pressure.

“The Vögtlin MFC’s are perfectly suited for our application

and perform beyond our expectations.

The smart units help us to manufacture perfect products.”

Eren Tuncer, Engeneering Manager, Appsilon Enterprise

MEMS or CMOS-based MFCs are best suitable. They provide a fast response and a minimum deviation from the required flow rate. Plug-and-play functionality, quality, and no warm-up periods improve user productivity. These mass flow controllers are often built inside cabinets near the reactor that also include heat-generating power supplies. The ambient temperature varies a lot.

Vögtlin Mass Flow Controllers have a unique way of compensating for changes in ambient and gas temperature, which strongly improves the repeatability. The MEMS technology ensures long-term stability without any drift as long as the gas supply is clean and dry.

You can easily define and purchase one separate MFC for each gas supply line (One MFC is suitable for up to 10 gases). It is also possible to build a custom-designed gas supply block where you exchange the MFC for another unit with only one bolt.

An integrated valve bank design, accurate internal mixing, and distribution pipe design help avoid operational risks and improve end-user comfort. Other benefits of these types of pre-assembled modules include reduced leakage points and reduced field installation time.

Units can be calibrated for multiple gases and parameters, which leads to significant reductions in spare part inventories and cost savings. MEMS type of MFC can work with dynamic ranges up to 1:1000. This means you can buy an MFC of 500 mln/min and run it at 0.5 mln/min.

Follow us:

Vögtlin Instruments GmbH

gas flow technology

St. Jakob-Strasse 84

4132 Muttenz, Switzerland

Vögtlin Instruments GmbH

is a company of TASi Measurement

©2024 Vögtlin Instruments GmbH Switzerland · All rights reserved.