| Profiles |

|

| Customer defined profiles |

Up to 15 user programmable profiles Profiles are preset configurations where the customer can set the gas, range, dynamics, totalizers, engineering units and reference conditions for up to 15 different applications |

| Performance Data |

|

| Accuracy |

A1 Core: ± 0.5% of user full scale ± 1% of measured value.

B1 Prime: ± 0.3% of user full scale ± 0.7% of measured value.

B2 Prime high accuracy: ± 0.3% of user full scale ± 0.5% of measured value.

For hydrogen applications:

B3 Prime H2: ± 0.3% of user full scale ± 0.7% of measured value.

B4 Prime H2 high accuracy: ± 0.3% of user full scale ± 0.5% of measured value.

User full scale = ~70…100% standard range. |

| Media |

All gases and gas mixtures that are compatible with the selected materials and for which data is

available in the NIST refprop database.

Contact the factory for more information. |

| Dynamic range |

Fixed dynamics: 1 : 100 for most gases* VADy® dynamics: up to 1 : 1000 (available for meter only) VADy® or a fixed dynamic range can be selected during order process.

This setting can be changed at any time using the Vögtlin Connect app.

*The dynamic range is gas and pressure dependent, higher pressures means lower dynamic range. |

| Response time |

Meter: 120 msec / Controller: 2000 msec (according to SEMI standard SEMI E17-1011)*

Update time mass flow value: 10 msec / Sensor sample rate: 1 msec

*With optimized filter settings. All filter modes and values can be set through the Vögtlin Connect app or the digital communication interface. |

| Repeatability |

± 0.2% of factory full scale (according to SEMI standard E56-0309) |

| Longterm stability |

Typical < 0.2% of measured value / year after tare |

| Power supply |

Meter: 15-36 Vdc, (200 mA@24Vdc, regulated) / Controller: 24 Vdc ±10%, (2000 mA@24Vdc, regulated)

Power in through M8-4P connection or optionally through D-sub connection

(ripple should not exceed 100 mV peak-to-peak) We recommend that the body of this unit is properly connected to ground |

| Operation pressure |

1 to 14 bar a |

| Temperature (environment/gas) |

-20 to +60 °C (-4 to 140 °F) |

| Humidity gas |

0-95% Rh (non-condensing) |

| Pressure sensitivity |

Prime and Prime H2 sensor: <0.05% factory full scale per bar (typical air).

Core sensor: <0.08% of factory full scale + 0.1% of measured value per bar (typical air). |

| Temperature sensitivity |

<0.02% FFS* per 1 °C of inlet gas temperature @ 7 bar a pressure

*Factory Full Scale (maximum flow range of the device) |

| Accuracy temperature |

Typically ± 0.5 °C (not certified) |

| Accuracy absolute pressure |

<0.5% MV (not certified) |

| Warm-up time |

<2 sec for full accuracy |

| Materials |

|

| Wetted parts |

Elastomers: FKM, EPDM, FFKM (valve seat). Full FFKM version upon request.

Body: Stainless-steel 316L (1.4404).

Valve (controller): 316 (1.4401), 416 (1.4005), 430F (1.4104).

Inlet filter: Stainless-steel 316 (1.4401), fastening stainless-steel (1.4122) or equivalent.

A1 core sensor: Stainless-steel 316Ti (1.4571), silicon, gold, glass, silicone encapsulation, PBT. 30GF, ceramics.

B1 + B2 Prime sensor: Stainless-steel 316L (1.4404).

B3 + B4 Prime H2 sensor: Stainless-steel 316L (1.4404) with gold coating. |

| Electronic housing |

Powder coated stainless steel |

| Integrated inlet filter |

50 micron SS316 (1.4401) filter. Fastener filter material stainless-steel (1.4122) or equivalent. |

| Wetted part surface roughness |

1.6 Ra µm or better (contact factory for lower Ra values) |

| Integration & Installation |

|

|

|

| Output signals analog |

Linear 4–20 mA or customer defined (max 20 mA), user selectable

Linear 0–5 Vdc or 0-10 Vdc or customer defined (max 10 Vdc), user selectable

mA output: 740 ohms maximum load resistance

Volt output: 1000 ohms minimum load resistance

All analog outputs are galvanically separated and protected. If used with analog signals add + as before 0.2% of FFS to the uncertainty |

| Setpoint signals analog |

Linear 4–20 mA or customer defined, (max 20 mA) user selectable

Linear 0–5 Vdc or 0-10 Vdc or customer defined, (max 10 Vdc) user selectable |

| Output signals digital |

RS-485 (Modbus RTU 2-wire)

The Modbus address can be set with 2 rotary switches on the outside of the housing.

All Modbus settings can be set through the Vögtlin Connect app. |

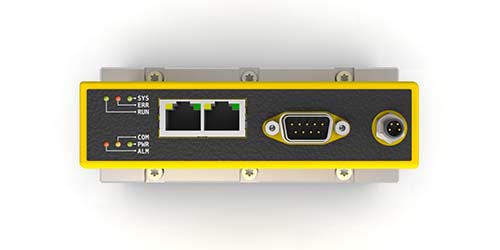

| Optional Profinet or EtherCAT |

Dual port RJ45 with integrated switch (easy to daisy chain)

RJ45 LEDs indicating link and activity on the network / Ethernet speed: maximum 100 Mbit

ProfiNet: PROFINET IO specification v2.33 / PROFINET IO devices conformance class B (RT) / Endianness: conform Siemens S7 (big)

EtherCAT: IEC standard IEC61158 / Endianness: little

EtherNet/IP™ coming soon. |

| Configuration interface |

Wireless Vögtlin Connect app available from Google Play store |

| Output I/O MOSFET |

On/off for external shut-off valve or alarm available through M8-4P connector

Contact type: MOSFET (open drain/collector)

Maximum voltage: 36 Vdc, Max current 500 mA (Polyfuse protected) |

| Electrical connection |

9-pin D-sub male (power and signals) and M8-4P connector (Power + I/O MOSFET output)

Optional 2 x RJ45 (EtherCAT / Profinet) |

| Process connection |

1″ BSPP female (1″G)

Optional ½” BSPP, 1″ Compression or Tri-clamp 50.5mm flange size (ISO) (see accessories tab) |

| Inlet section |

None required if our standard inlet filter / conditioner is installed

Without filter / conditioner a 10 D straight inlet is recommended

The inlet filter can be deselected at time of order |

| Pressure drop |

Meter: Standard 400 mbar at factory full scale air venting to atmosphere (with filter / conditioner)

Optional: 325 mbar at factory full scale air venting to atmosphere (without filter / conditioner)

Pressure drop is dependent on operating pressure (higher pressure = lower pressure drop)

For more information please refer to your sales partner

Controller: Min. pressure difference required for 1400 ln/min (air) < 2 bar

Contact your sales partner for other pressure drop requirements |

| Mounting orientation |

All orientations are possible |

| Weight |

Meter: 3.7 kg, Controller: 8.7 kg (excluding ethernet and fittings) |

| Safety |

|

| Test pressure after production |

28 bar a |

| Maximum overpressure sensor |

Core Sensor: 28 bar a, Prime and Prime H2 Sensor: 90 bar a |

| Burst pressure |

Meter: 100 bar a, Controller: 70 bar a |

| Leak rate |

< 1 x 10-6 mbar l/s He |

| Ingress protection class |

IP54, if IP54-D-sub is used (see accessories tab)

For optional EtherCAT/Profinet: IP40

For additional safety information please consult the d·flux safety information sheet available on our website |

| Certifications |

|

| EMC |

IEC/EN 61326-1, IEC/EN 61000-6-2/4 |

| ATEX certification |

None |

| Material certificates |

To be released in 2023 (available for meter only) |

| FDA compliance |

To be released in 2023 (available for meter only) |

| PED |

Fully compliant. Since the unit has 1″ process connection, complies with the SEP, as defined in article 4, paragraph 3 of the Pressure Equipment Directive (PED) (2014/68/EU) |

| RoHS / REACH |

All components comply with Directive 2002/95/EC (RoHS) and the REACH guidelines |

| Warranty |

3 years, excluding cases of corrosion

|