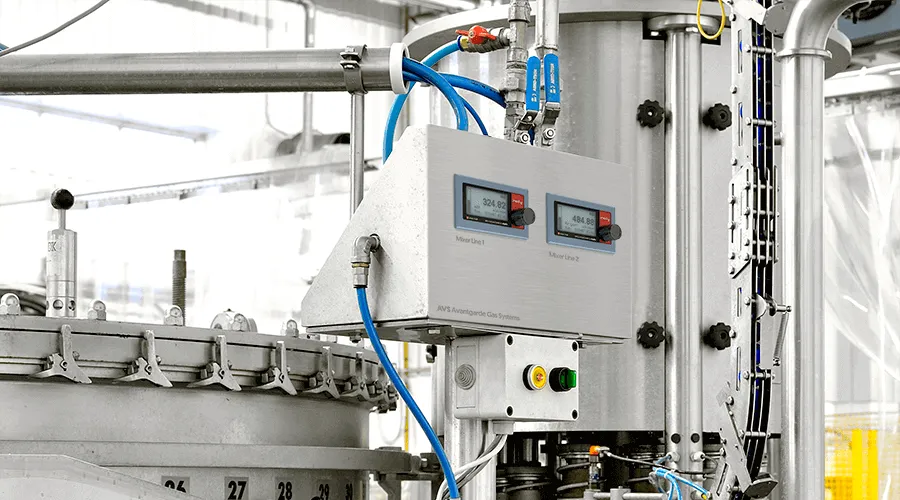

Gas sampling is the first step in the collection of data that guards process variables, monitors emissions and verifies that processes are running consistently.

In the analytical world the red-y compact 2 meter is used as the heart of a reliable automatic, low cost gas sample taking device. Emission or environment measurements often demand periodic samples of a fixed amount of gas and collect these in a container or sample bag.

For example every hour a 100 scc sample. The red-y compact 2 meter with its optional smart alarm module has the complete solution without the need of any PLC to control the process.

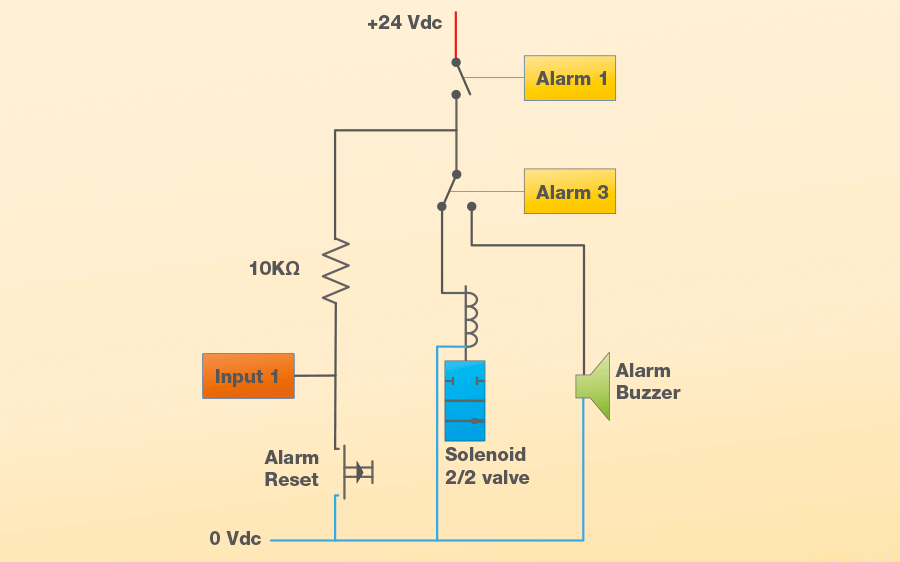

Figure 1: Basic electrical diagram of periodic gas sampling system

The system operates on 24 VDC and a very simplified diagram can be seen in figure 1. The compact 2 alarm module has 3 alarm points that are individually programmable for different alarm functions, such as totalizer, window, high and low alarms. We will also make use of the timer functions and the ability to reset the alarms and totalizer with an I/O input on the alarm module.

We program Alarm 1 as a totalizer alarm with the sample volume we want to collect in each sample, which in our example is 100 SCC (Standard cubic centimeters).

With the alarm function we can program an alarm duration between 100 msec and 2.78 hours. This duration determines the interval between the sample collections. Once the process starts, the solenoid valve opens and a pre-set amount of gas flows into the sample bag or container. Once the defined amount is reached, the Alarm 1 closes the solenoid valve and stops the gas flow Alarm 1 remains active for the pre-programmed time, in our example 1 hour.

After this hour, Alarm 1 automatically resets and the totalizer returns to zero. The solenoid valve is reactivated, the gas begins to flow and the totalizer starts counting again until the pre-set value is reached. This process repeats, allowing a sample of 100 SCC to flow into the sample container every hour.

Alarm 3 serves a diagnostic purpose and is triggered when:

In such cases the reset button must be pressed to deactivate the alarm and continue the process. There are numerous other options possible and each system can be individually modified, like flushing, filtering, pressure reduction or gas drying. Many users of these systems obtain the battery powered, high-precision red-y compact to verify if the flow meter in the field is working properly or if it requires calibration or cleaning. The red-y compact has a large internal diameter flow channel, a low pressure drop, is temperature compensated and measures the mass flow independently of pressure and temperature changes.

Flexibility

It is impossible to describe every process where these flow meters are used, but if you see a VA meter for gas and you want to improve your process, talk to the experienced Vögtlin engineers and they will be pleased to help you to find the right solution.

Conclusion

Customers around the world benefit from our products in analytical fields, research and development, light industrial applications, semiconductor segments, and other areas. We often hear from users, “The great thing about Vögtlin Thermal Mass Flow instruments is that you installed and adjusted them, you don’t have to think about it because they work so reliably.”

Vögtlin’s global network of distribution and sales partners will assist you in selecting the equipment that best matches your application and specific needs. Local service centers in the USA, China and Europe provide comprehensive after-sales support.

Follow us:

Vögtlin Instruments GmbH

gas flow technology

St. Jakob-Strasse 84

4132 Muttenz, Switzerland

Vögtlin Instruments GmbH

is a company of TASi Measurement

©2024 Vögtlin Instruments GmbH Switzerland · All rights reserved.