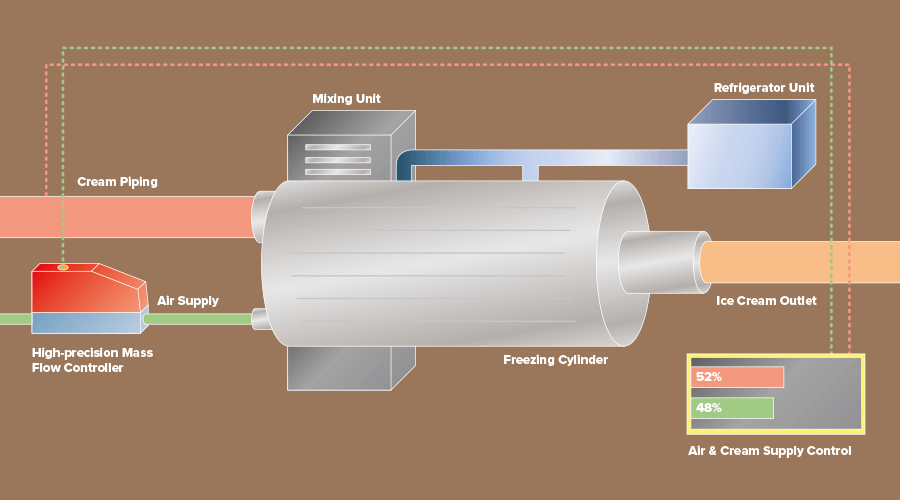

What makes a good ice cream? Besides fresh ingredients and dedicated specialists, the secret lies in the air: In the production process air must feed into the paste at a specified proportion.

During ice cream manufacturing, a mixture of paste and air is fed into a freezing cylinder then blended by a scraper. Simultaneously, a cooler on the freezing cylinder wall freezes the paste.

Blades on the scraper rake frozen paste off the cylinder wall. In this process, the paste is continuously frozen, scraped, and mixed with the air to create ice cream.

To produce good-tasting ice cream, the process must feed air into the paste at a specified proportion (mostly 50%). Controlling the ratio of paste and air by the flow controller is very critical for ice cream quality and consistency.

MEMS technique of the MFCs provides for a 350ms rapid response. Plug-and-play functionality and no warm-up periods improve user productivity.

Vögtlin Mass Flow Controllers have a unique way of compensating for changes in ambient and gas temperature, which strongly improves the repeatability.

The MEMS technology insures a long-term stability without any drift as long as the gas supply is clean and dry. Dual temperature calibration avoids error caused by ambient and gas temperature better than alternative mass flow controllers.

Follow us:

Vögtlin Instruments GmbH

gas flow technology

St. Jakob-Strasse 84

4132 Muttenz, Switzerland

Vögtlin Instruments GmbH

is a company of TASi Measurement

©2024 Vögtlin Instruments GmbH Switzerland · All rights reserved.