Low-E glass incorporates multiple layers of metal or other compounds as a surface coating that provides high transmittance for visible lights and high reflectance for mid-IR and far-IR lights.

The coating benefits are excellent heat insulation and favorable light transmission compared to standard and traditional-coated glass used in the building industry.

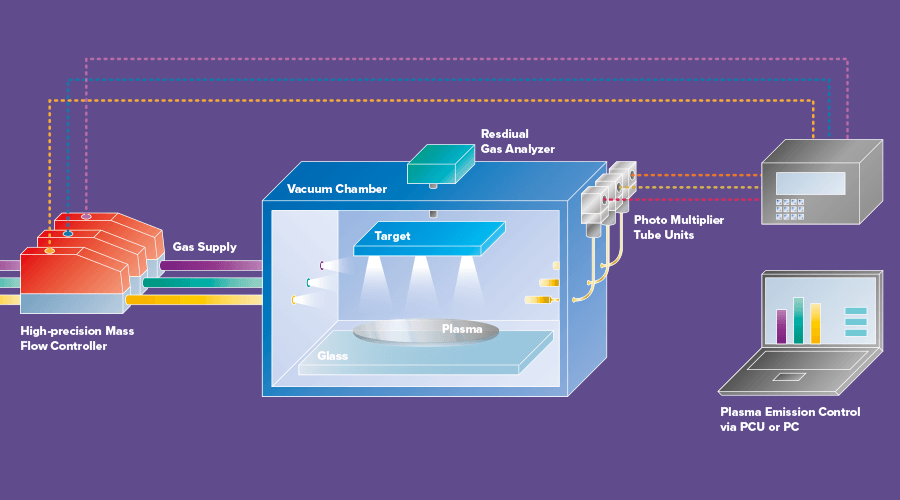

In Low-E glass manufacturing, vacuum magnetron sputtering is a common coating technique used across the globe. In this process, gas flow (inert gas Ar or reactive gas O2 and N2) in the vacuum environment must be controlled with a top-quality mass flow controller (MFC) to maintain a stable vacuum level.

With the magnetron target acting as the cathode, a high voltage provided by an AC or DC power supply will ionize process gas to generate plasma. Electrons move at high speed under the joint force of the electric field and magnetic field, colliding with gas molecules and creating more positive ions and electrons.

After gaining a certain energy, positive ions in the electric field will hit the cathode target material. The sputtered target material deposits on the glass substrate to form thin films. Uniform and consistent film layers are required.

Inflow gas should be maintained at a very stable level in the coating process to avoid uneven coating and significant spots and negatively impacting the general energy of particles in the coating, which is not favorable for reactive deposition. A complicated gas distribution system requires numerous of process gas branches. Installation and commissioning of single channel gas circuits are tedious with heavy work load. In addition, this system typically reduces efficiency, and generates multiple leakage points. Human operation errors (wrong connection of gas mixing and connection circuits) also can negatively impact operations.

MEMS technique of the MFCs provides for a 350ms rapid response. Plug-and-play functionality and no warm-up periods improve user productivity.

Vögtlin Mass Flow Controllers have a unique way of compensating for changes in ambient and gas temperature, which strongly improves the repeatability. The MEMS technology insures a long-term stability without any drift as long as the gas supply is clean and dry.

Only one bolt is required to fix an MFC, allowing faster and more accurate removal/assembly.

An Integrated valve bank design and accurate internal mixing and distribution pipe design help avoid operational risks and improve end user comfort. Other benefits include saving of consumables for gas source pipes, reduced leakages points and field installation time as well as an easy and accurate realization of complicated gas mixing and distribution process.

Units can be calibrated for multiple gases and parameters, which leads to significant reductions in spare part inventories and cost savings.

Follow us:

Vögtlin Instruments GmbH

gas flow technology

St. Jakob-Strasse 84

4132 Muttenz, Switzerland

Vögtlin Instruments GmbH

is a company of TASi Measurement

©2024 Vögtlin Instruments GmbH Switzerland · All rights reserved.