| Measuring & control ranges Pressure |

|

| Pressure control |

Absolute, differential or gauge pressure

Standard measuring ranges from 30 mbar up to 10 bar (graded)

Turndown ratio: 1 : 100 |

| Back pressure control |

Absolute, differential or gauge pressure

Standard measuring ranges from 30 mbar up to 10 bar (graded)

Dynamic range depending on the application |

| Measuring ranges flow |

|

| Air/Full scale freely selectable |

Body size ¼” from 0 … 25 mln/min to 0 … 60 ln/min

Body size ½” from 0 … 60 ln/min to 0 … 450 ln/min |

| Turndown ratio & accuracy Flow |

|

| “Standard” |

Accuracy: ± 1.0% of full scale*

Turndown ratio: 1 : 50 |

“Hi-Performance”

(up to 150 ln/min) |

Accuracy: ± 0.3% of full scale + ± 0.5% of reading*

Turndown ratio: 1 : 100 |

|

Pressure controller with external transmitter, special measuring ranges (e.g. 0-20 Pa) & customer-specific solutions on request |

| Performance Data |

|

| Media (real gas calibration) |

Air*, O2*, N2, He, Ar, CO2, H2, CH4, C3H8 (other gases and gas mixtures on request)

*O2 & N2 are calibrated with air |

| Response time Flow Measurement |

± 80ms

depending on device configuration & according to SEMI standard E17-1011, 5-100% of range under optimized conditions |

| Response time Pressure Measurement |

150ms |

| Response time Pressure Control |

Depending on the measuring section |

| Repeatability |

± 0.2% of full scale (according to SEMI standard E56-0309) |

| Longterm stability |

< 1% of measured value / year |

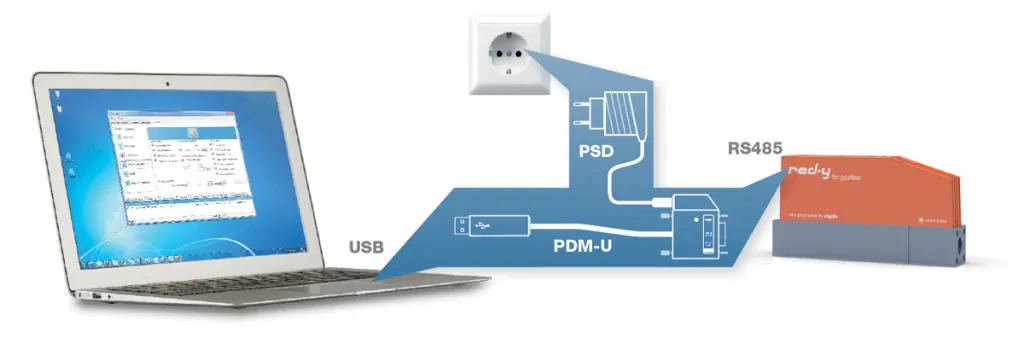

| Power supply |

24 Vdc (18 – 30 Vdc), 15 Vdc on request |

| Current consumption Standard |

Meter: max. 100 mA; Controller: max. 250 mA

(with valve type 8 max. 490mA) |

Current consumption

Profinet RT / EtherCAT |

Meter: max. 125 mA; Controller: max. 340 mA

(with valve type 8 max. 560mA) |

| Temperature (environment/gas) |

0 – 50°C |

| Body Materials |

Anodized aluminium,

optional stainless steel electropolished 1.4305 or 1.4404 |

| Seals |

FKM, EPDM, optional FFKM |

| Pressure |

Vacuum up to 10 bar g |

| Pressure sensitivity |

<0.2% / bar of reading (typical N2) |

| Temperature sensitivity |

0.025% FS measuring range type / °C |

| Warm-up time |

<1 sec. for full accuracy |

| Integration |

|

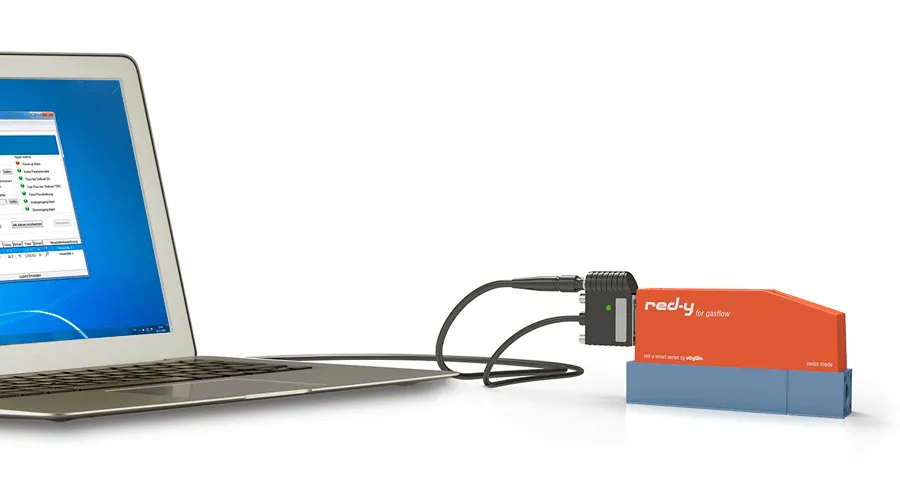

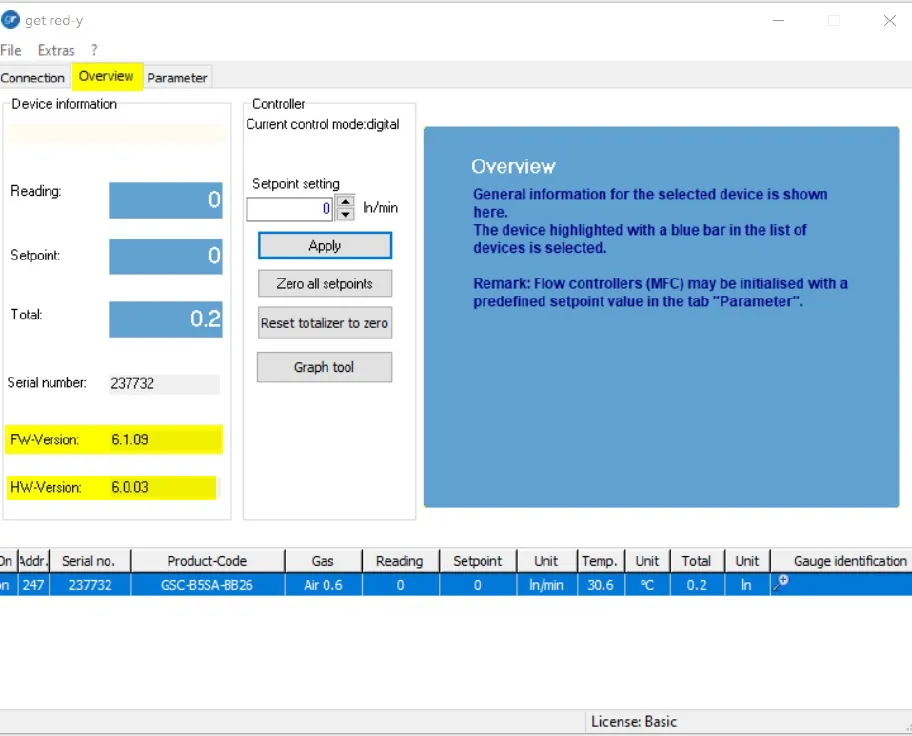

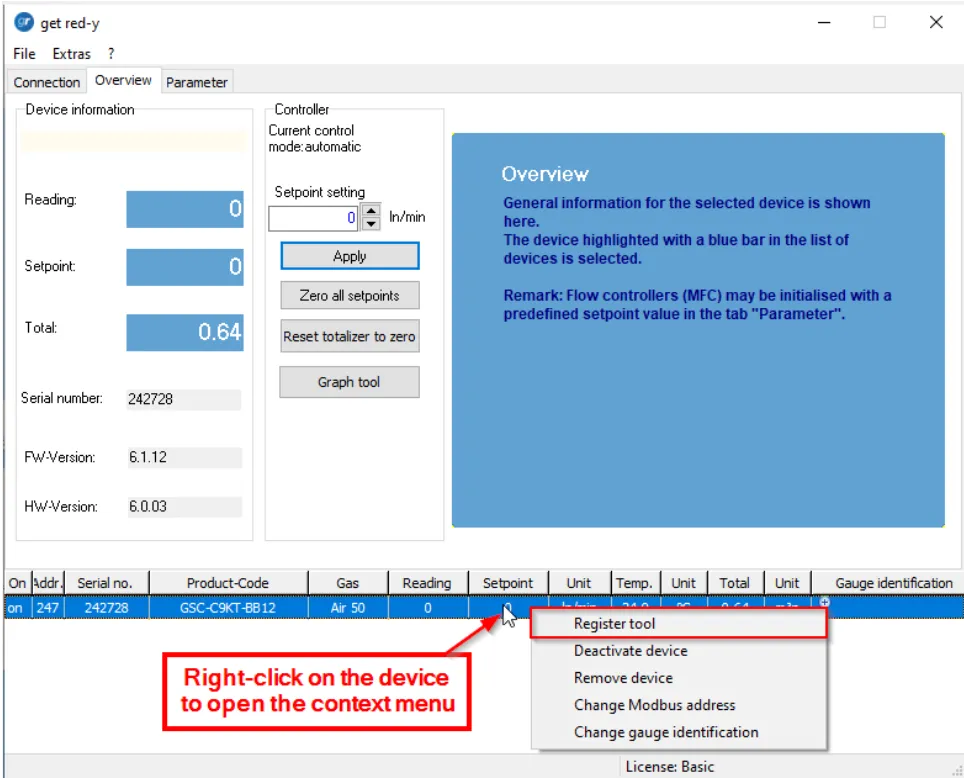

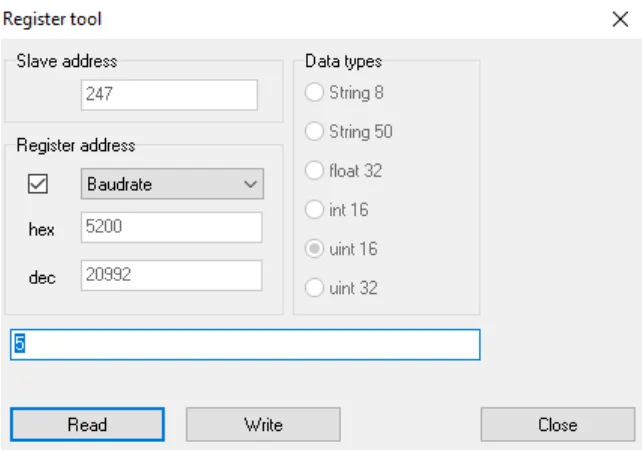

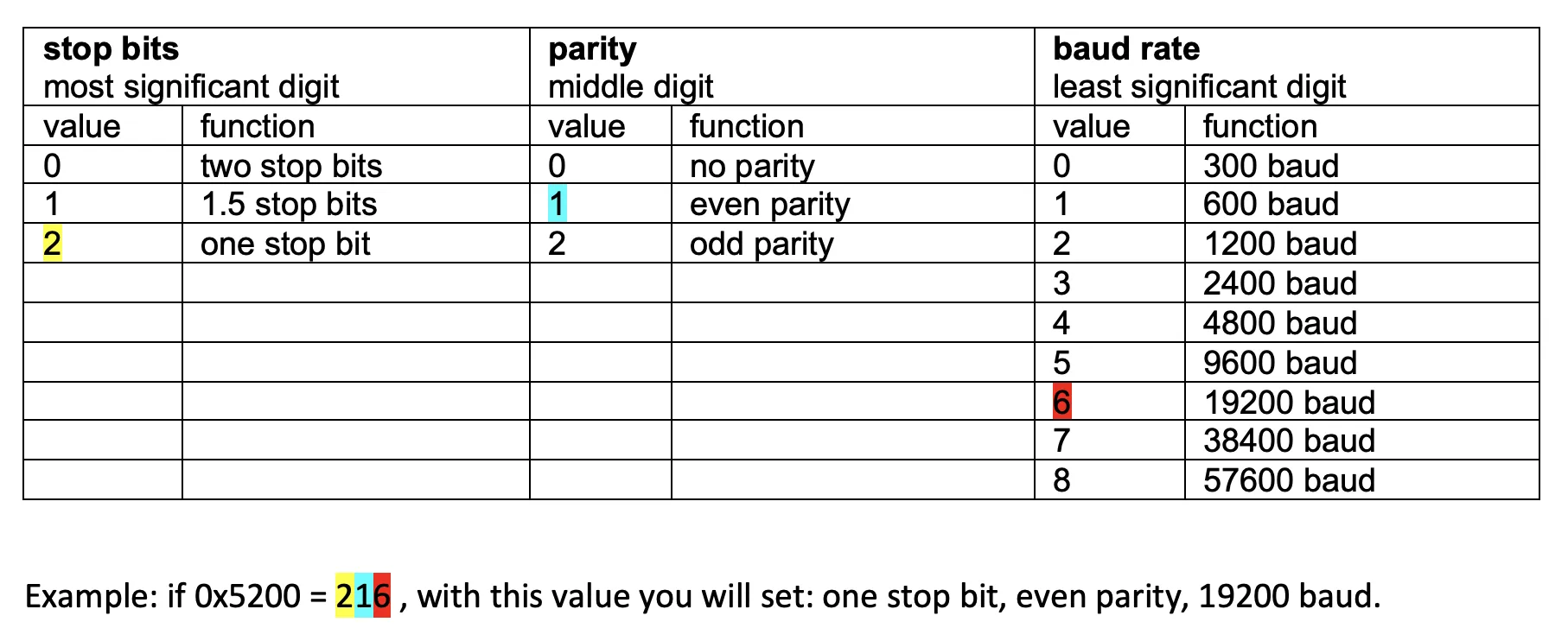

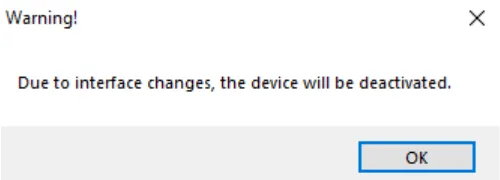

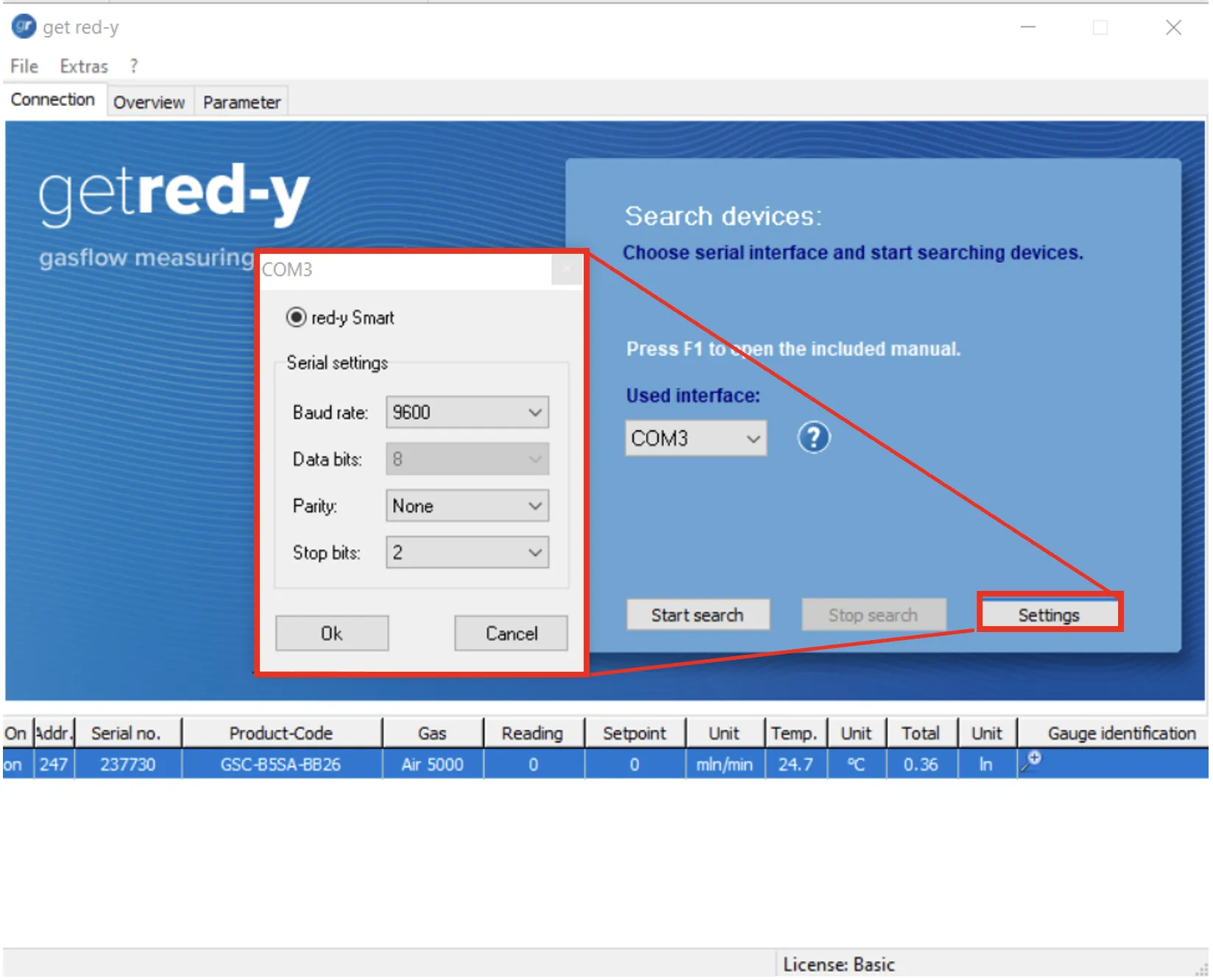

| Output signals digital |

RS-485; Modbus RTU (Slave); Lab View-VIs available

Option: ProfiBus DP-V0, DP-V1 / Profinet RT / EtherCAT |

| Output signals analog |

0..20 mA, 4..20 mA, 0..5 V, 1..5 V, 0..10 V, 2..10 V |

| Analog setpoints |

Realizable with AD-converter (on request) |

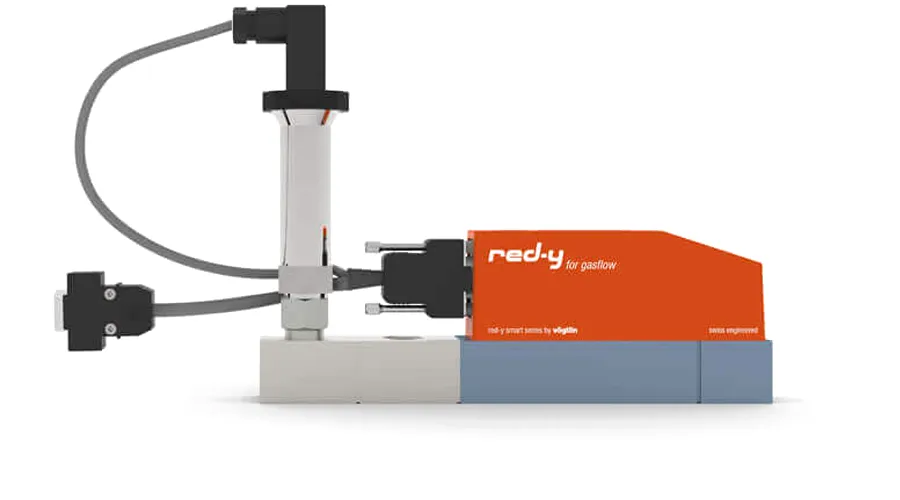

| Process connection |

G¼” (BSPP* female) up to 60 ln/min,

G½” (BSPP* female) up to 450 ln/min

*British Standard Pipe Parallel |

| Inlet section |

None required |

| Electrical connection |

Sub D plug, 9 pole |

| Mounting orientation |

Any position (consult manufacturer above 5 bar or vertical mounting) |

| Safety |

|

| Test pressure |

16 bara |

| Leak rate |

< 1 x 10-6 mbar l/s He |

| Ingress protection class |

IP50 or IP67 |

| EMC |

EN 61326-1 |