Please keep in mind that the serial settings of your device and the get red-y software (or your PLC) must be set identical to allow communication between them.

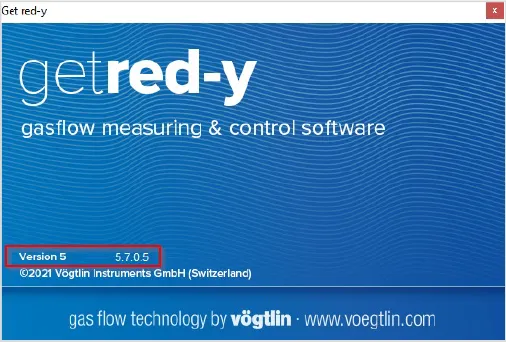

Parity and stop bits settings, in addition to the baud rate configuration, are only available for smart6 device from the firmware v6.0.14, and supported by get red-y software from v5.7.0.6.

Settings on your device:

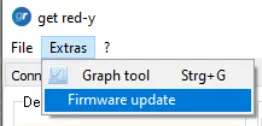

First, change the settings on your device with the help of the Register Tool from get red-y 5 software. For the release of this Register Tool function, you will have to ask a daily password from our service department.

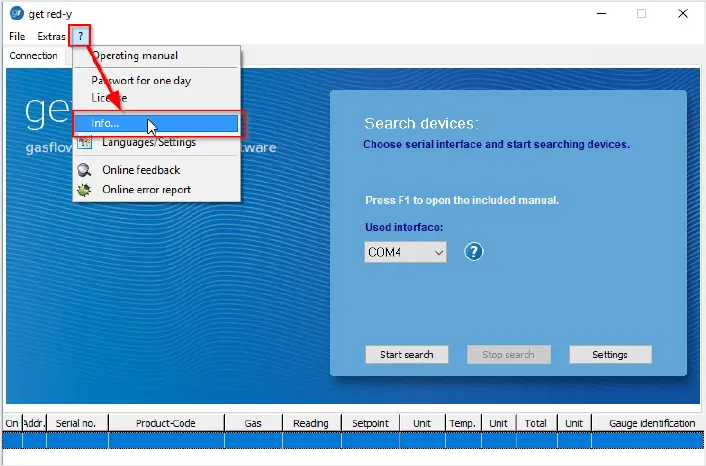

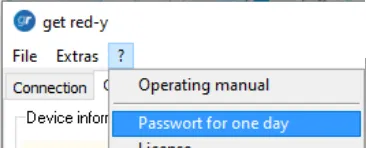

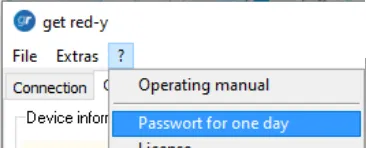

1. Start get red-y and select the question mark (?)

2. Click on “password for one day” and enter the daily password received from the customer service

3. Click on “Password for one day” and enter the daily password you received from us

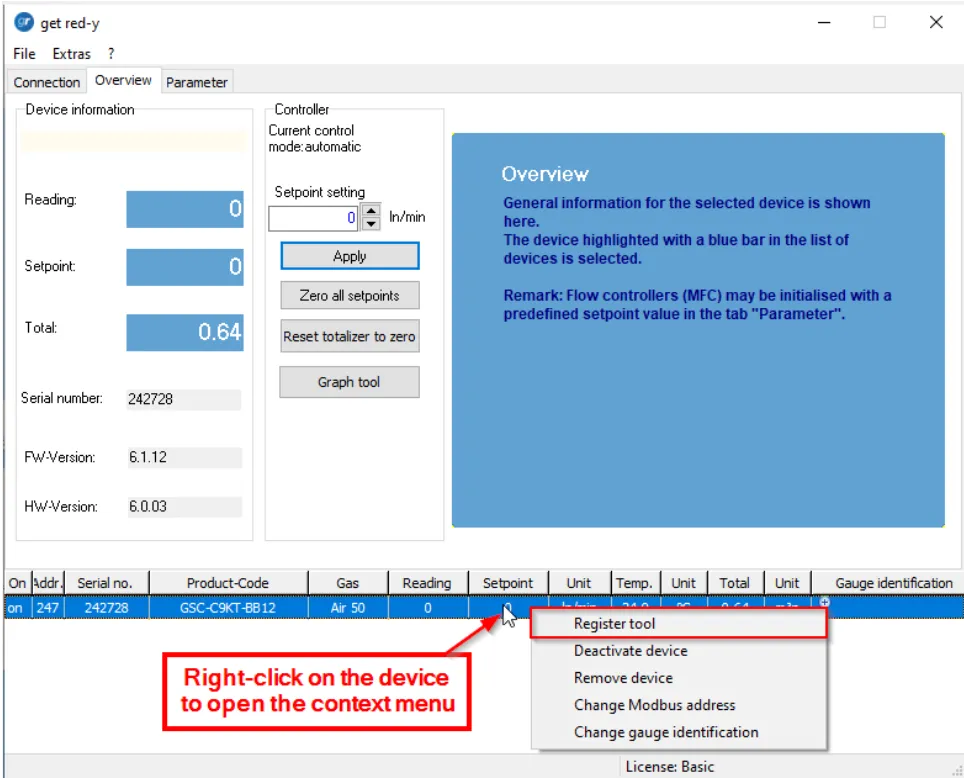

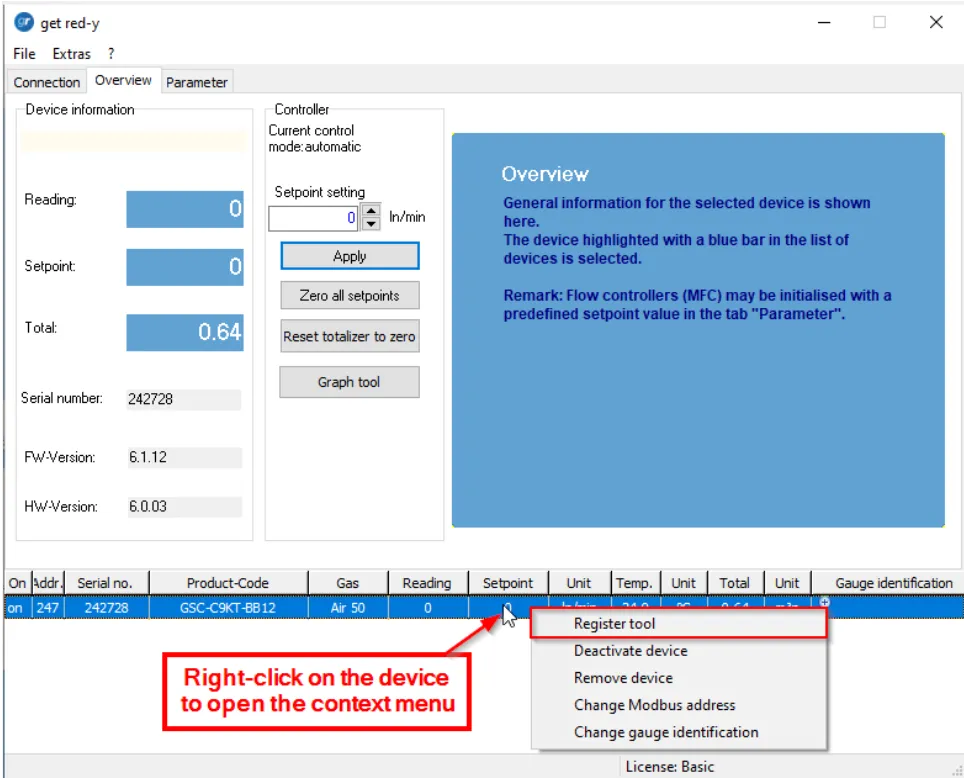

4. Click on the right mouse button within the device list to open the context menu for a specific device:

5. Select “Register Tool”

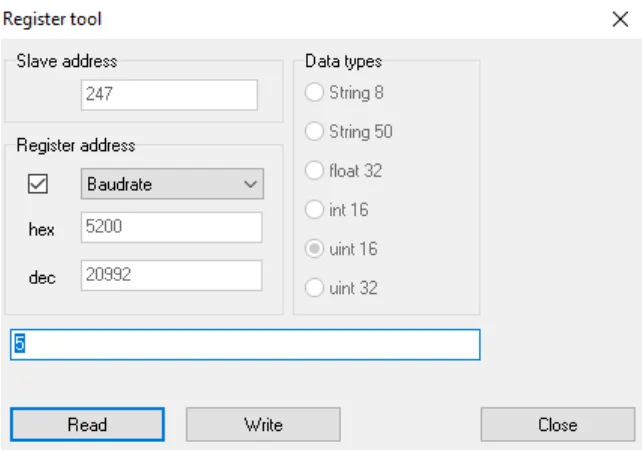

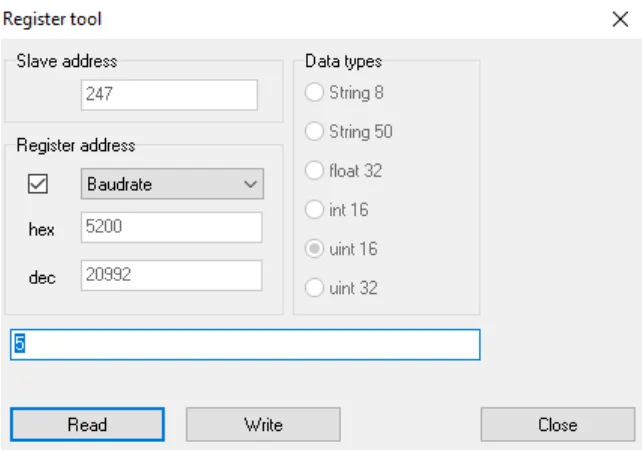

6. Within the Register addresses filed select “Baudrate” (=register 0x5200)

7. By selecting the “Read” button the default value “5” will appear.

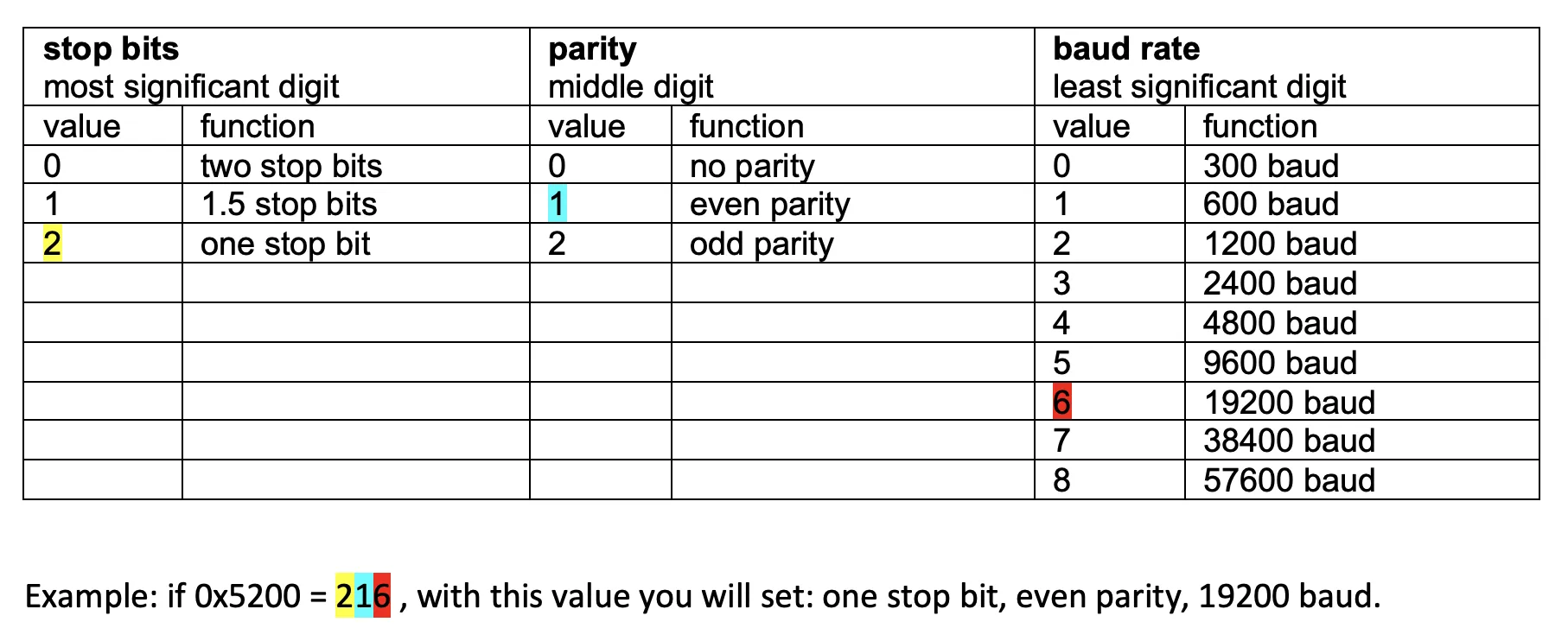

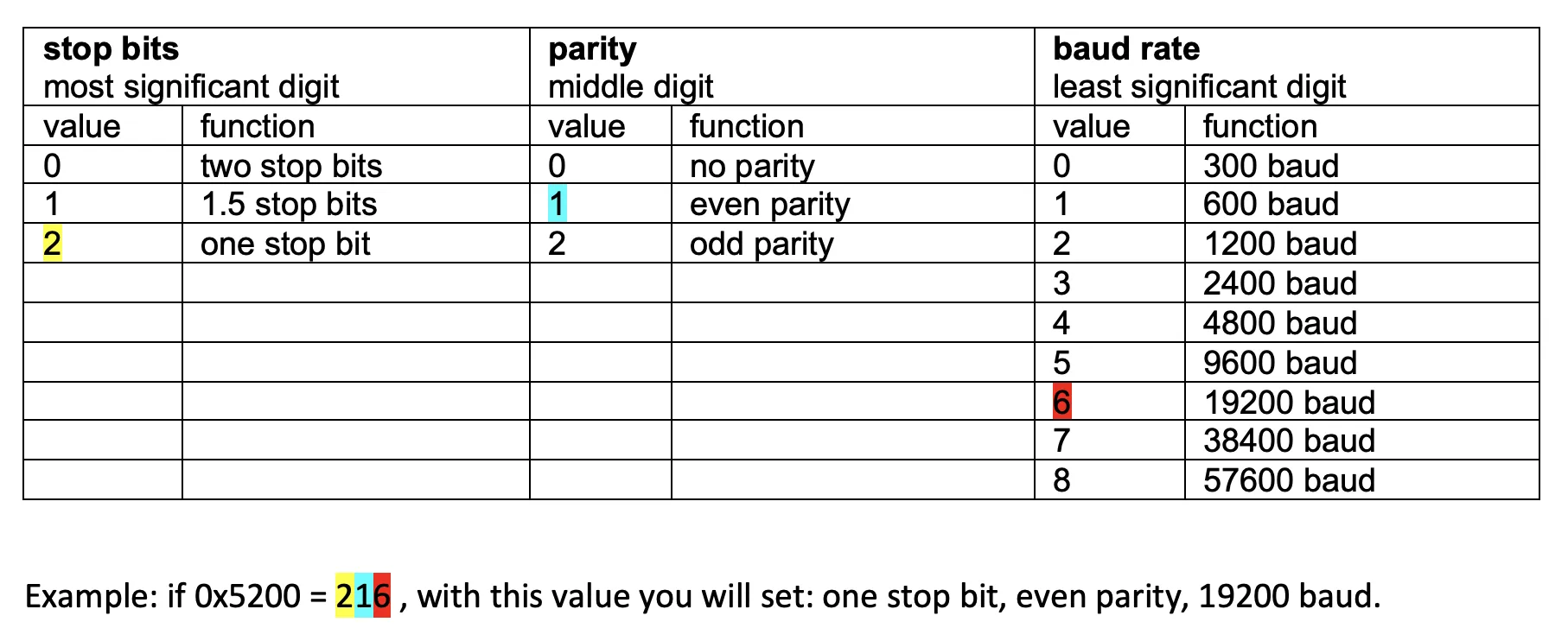

Note: To change Baud rate, parity and Stop bits, you will have to select a unique value with 3 ditigs with the desired setting from the table below.

8. Now you will have to enter a 3 digits value, and select “Write”

As the changes are not anymore only done on the Baud rate, we will have to use 3 digits that will always operate a change on all three parameters.

The register now has three digits, which control the behaviour as given in the following table:

9. As the default communication settings under the get red-y software are now different from those on your device, the Error message “interface change” appears.

Settings get red-y software (or PLC):

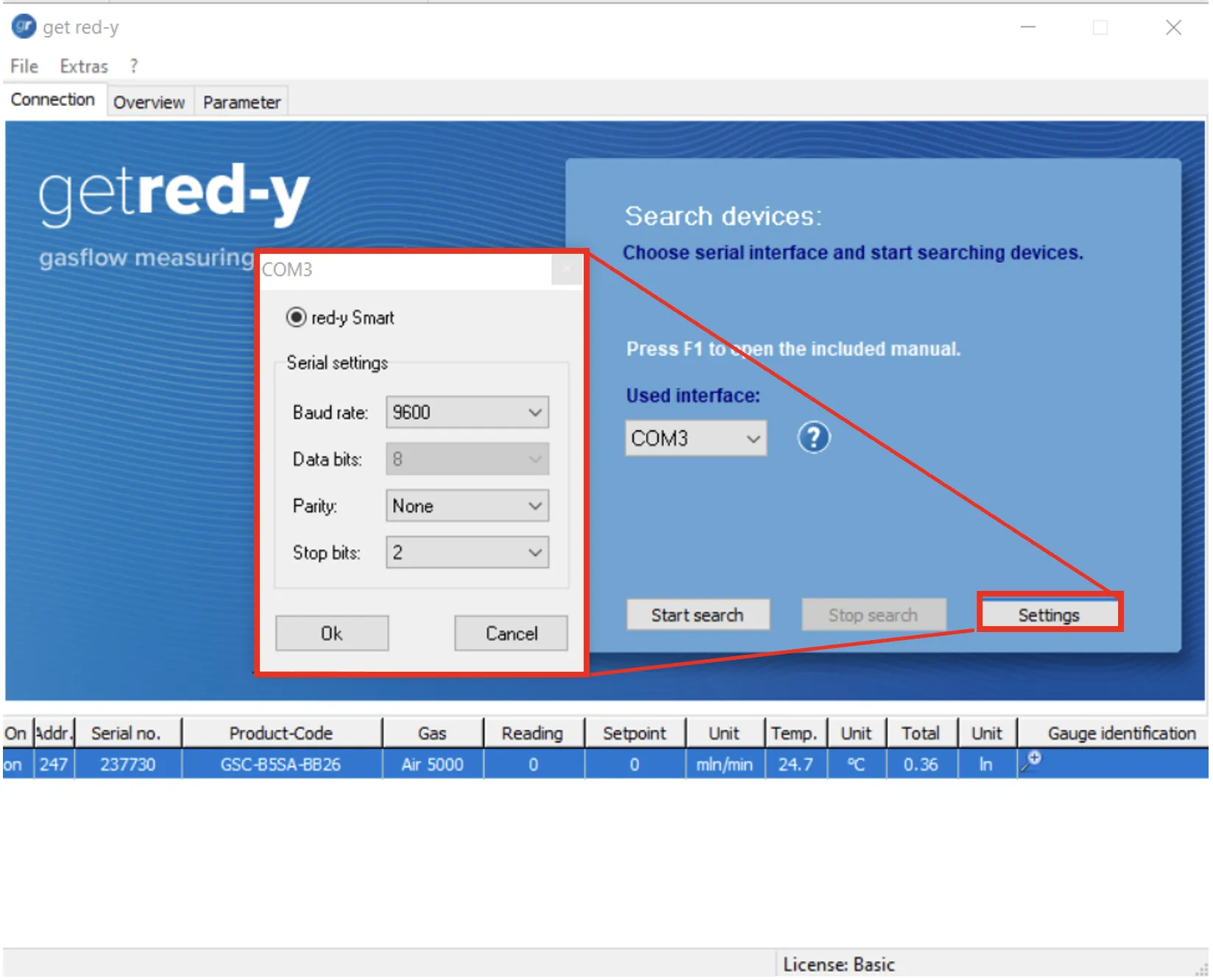

Note: In order to find the device via the get red-y software, the serial settings of the software must match the settings of the device.

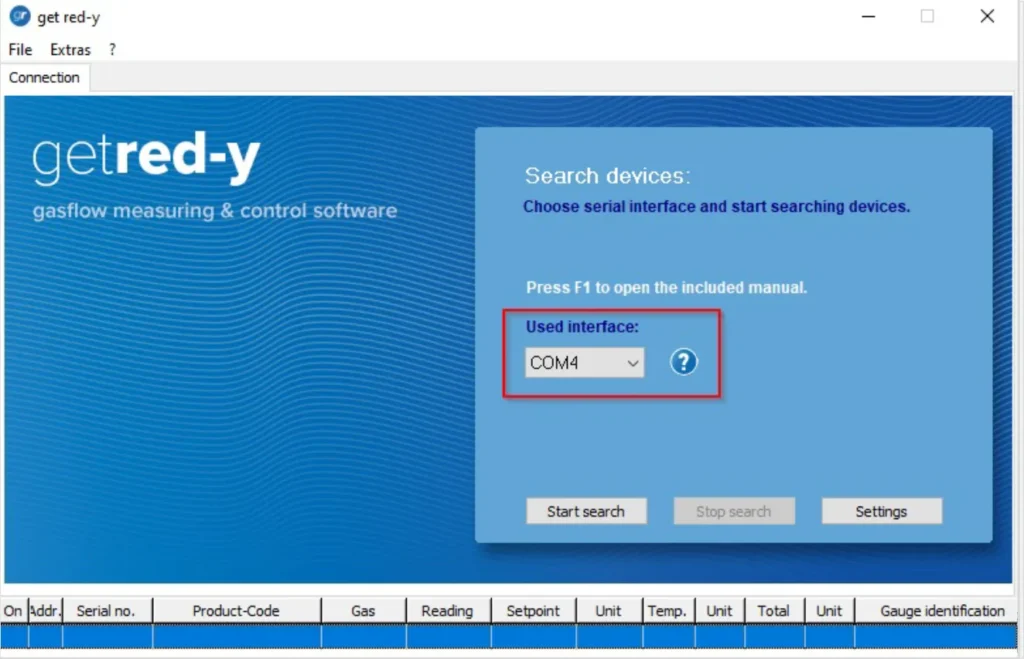

10. Open get red-y software

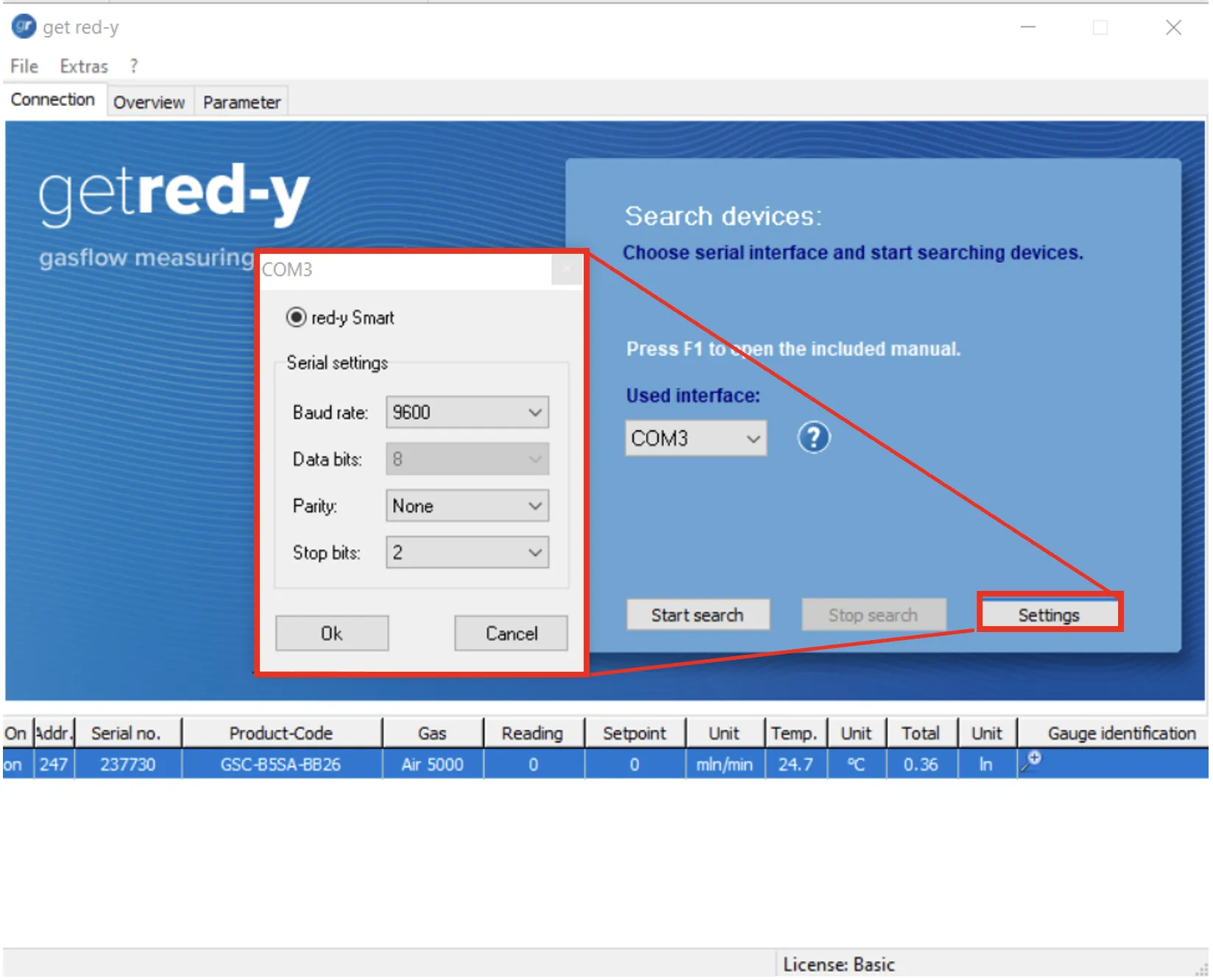

11. Select Settings

12. Set “Stop bits”, “parity”, “baud rate” according to the device settings and confirm with Ok.